Energy Systems & Technologies

Why make the energy shift? You'll improve your bottom line today and well into the future. When generating electricity onsite, what your neighbor has may not be the best for your business. Choosing the right technology mix and sizes are critical. Your technology mix will depend on how you use energy and whether you want to maximize savings, protect sensitive equipment or ensure 24/7 backup.

Energy Your Way:

Onsite Options From Pacifico Power

Click or tap the radial buttons for more info.

How Solar Works

PV

Photovoltaic (PV), or solar systems convert light into electricity. The key component in the system is a photovoltaic. Sunlight strikes the silicon wafer knocking electrons loose which can only flow in one direction, creating electrical current. Photovoltaic modules produce energy in direct current (DC) and is typically passed through an inverter to match the alternating current (AC) used in most facilities and devices.

A fixed solar array is one that does not rotate to follow the sun throughout the day (tracking). On average, a fixed solar array produces energy for about 7 hours per day when the sun is out. However, this can vary significantly based on the season, latitude, cloud cover, angle, and the tilt of the modules. Heat and soiling also reduce production.

The energy production of solar panels is too variable to connect directly to facilities and equipment, so it typically goes straight to the grid in exchange for credits or other payment. Pairing solar with batteries and switchgear can allow for the energy to be used locally.

The Sun's Path During

Summer and Winter

Historical Mean *LCOE Values

*Levelized Cost of Energy

Source: energyinnovation.org

The cost of solar modules has come down enough in the last 10 years that solar energy is now the cheapest form of energy. Electricity from solar energy from huge arrays in sunny locations is sold for less than $0.02 per kilowatt. The cost of a solar system is dependent largely on the system size and the mounting method – ground mount, rooftop or carport. The cost is higher for smaller commercial and industrial systems, but it is still often less than retail energy cost.

Batteries

Large energy storage systems, or batteries, extend the value of intermittent energy resources such as wind and solar. Inexpensive but intermittent energy is stored when there is a surplus and released (dispatched) when the resource dips in production or when a substitute is needed for grid energy when it is most expensive.

Many battery technologies, such as redox flow, flywheel, and compressed air, exist for different use cases. But most battery storage systems currently use lithium-ion cells like those found in laptop computers. In large energy storage systems, battery cells are joined together and connected in a series with a computer, or battery management system (BMS), that controls charging and discharging. Like solar systems, a battery storage system uses inverters to convert the energy stored as direct current (DC) into the more practical alternating current (AC).

Energy System With Solar,

Plus Batteries

One cost of using a battery system is lost energy. Round-trip efficiency measures how much energy is lost during the charging, discharging, and inversion processes. Lithium-ion batteries are superior in round-trip efficiency and represent 80–90% of installed energy storage systems today

Batteries are for savings

Batteries can be used to save on energy costs when there are differences in prices based on the time of day, known as time-of-use (TOU) rates. The difference between peak (highest) and off-peak (lowest) rates can be $0.10 cents per kilowatt hour or even higher, and it's generally greater in the summer than in the winter. The batteries can store energy when it is least expensive and dispatch the energy when it is most expensive.

Recently, utilities began dividing their energy charges into two main buckets: 1) the amount of energy used and 2) the maximum amount of energy used by the customer at any one time, known as demand. Many tariffs actually have two demand charges—one for the highest energy demand in the billing period and another for the highest energy demand during the on-peak periods in the same billing period. Demand charges can be more than 50% of a customer's bill. Batteries are excellent at reducing demand charges. Batteries can be programmed to store energy until the user is nearing a peak point in energy consumption and release the energy at the same time so the energy drawn from the utility stays flat or even decreases. In this way, the utility would not see the customer's demand peak, as illustrated here.

Optimization of how and when a battery charges and discharges requires sophisticated data analysis and controls. The system considers both known values (current value of energy, energy reserves available, current demand) and unknown values (future value, future demand, future production). Past energy consumption patterns help set a discharge profile, but good software controls can continue to learn from consumption and production patterns to get the most value from an energy system.

Between government incentives, reduced cost, and new smart controls, batteries now frequently pay for themselves and add additional value by shifting energy usage and reducing demand charges.

EV Charging

Electric vehicle (EV) charging is a great addition to an on-site energy project. When added together with solar, batteries, and frequently new shade canopies, the impact of the project is felt and appreciated by all the employees and customers, not just the accountants.

There are three key considerations to take into account as you plan to add charging infrastructure.

Technology

There are three levels of EV chargers, differentiated by the charging speed.

| Level | Speed | KW Power | Approximate time to fill a 50 KWh battery |

|---|---|---|---|

| Ⅰ | Slow | 2 - 6 | 8 - 22 hours |

| Ⅱ | Fast | 7 - 22 | 2 - 7 hours |

| Ⅲ | Rapid | 43 - 150 | 30 minutes - 1 hour |

Why not simply go for the rapid charging every time? Because your current infrastructure may not be sized sufficiently to move that level of power and upgrades from your utility could be very costly. The chargers themselves, and the materials needed to connect them also are far more expensive with increased power. Also, depending on the design, the power usage could increase a building's demand charges from the utility.

On the other hand, slow chargers are quite inexpensive and will not require system upgrades. Some businesses may need rapid charging for their fleets, but in most cases the lower cost chargers will suffice.

We can evaluate your site and present options with prices for adding EV charging.

Economics

The bottom line is that adding chargers will add both equipment and energy cost but can also be a revenue center if desired. As a business hosting charging stations, you can choose the economic model that is right for you.

Additionally, businesses may choose to add an hourly fee to incentivize drivers to move their car as soon as it is charged to free the space for others.

If your company is expecting a significant increase in EV charging needs, for example a car dealership or delivery service adding an EV fleet, the impact on your infrastructure and electricity consumption will be quite significant. The decisions made early on may save significant costs down the road. Contact us and we can help you plan for the future.

| Cost impact to your business | Cost to the patron | |

|---|---|---|

| Subsidized | You absorb all or part of the cost. Businesses do this to attract more retail customers, or to reward employees. | Anywhere from free to minimal cost below market value. |

| Pass through | None | Dynamic market rates, depending on your rate tariff and the cost of energy at the time of the charging. Note: paired with a solar system, daytime electricity will likely be the lowest cost. |

| Revenue center | The business makes profit on the sale of energy, adding a fee on top of market energy rates. | A cost above both retail cost of energy and amortized cost of the equipment. |

Impact on your utility bills

Typical commercial customers pay both a demand and energy charge. Your demand will certainly be affected by your EV chargers particularly if you have rapid chargers. It is important to understand your current utility rate structure when deciding on your preferred charging technology.

Charging costs can generally be passed on to the EV patrons, but there is a small chance that significant usage could impact the utility rate tariffs your main building is eligible for.

Utilities may propose you add a new meter for the EV chargers and may even offer a sweetheart deal to have your demand charges covered for the first year or two. We would be wary to take this route. Demand charges are the primary reason for the significant utility price increases recently, and once the sweetheart deal expires business you may find the increase to your EV charging rate to be significant.

The bottom line is that it might be a simple a pass through, but it could change your energy profile and costs. Let us help walk you through it.

The Microgrid in Action

Microgrid

A microgrid is an electrical system in which the facilities and equipment are connected to the grid, but that can also be isolated from the grid and still maintain power. Although microgrids can be designed to operate indefinitely, they are more often engineered to maintain power for a matter of hours, not days.

There are three basic components of a microgrid:

- Generation – A microgrid needs a local source of power. This may be solar, wind, fuel cells or generators and is likely combined with batteries. Microgrids frequently include a dispatchable energy source, one that can be turned on or off as needed such as a diesel generator.

- Switchgear – Some infrastructure is needed to disconnect from and reconnect to the grid – known as ‘islanding' – and to reconnect when needed.

- Controller – A proper control system knows when islanding is necessary and it sends the signals to island, initiate generation, use batteries and flip switches.

A microgrid allows the customer to be immune to disruptions in energy supply from the grid. A microgrid may also help control costs by providing predictable generation on-site and reducing the use of increasingly expensive grid energy.

Battery storage has become more relevant and useful in microgrids because of its declining cost and increased functionality and controls.

Inverters

Energy is generated in direct current (DC), yet the grid and devices operate on alternating current (AC). The difference requires the energy to be converted using an inverter. Inverters take in DC energy and pass it through a switching mechanism up to 60 seconds per second, reversing polarity to create alternating power. There is loss in converting the energy, so the AC output will be approximately 80% of the DC input.

DC (to) AC

The Conversion of direct current (DC) into alternating current (AC).

Cogeneration

The simultaneous production of electricity and steam from a single fuel source, delivering energy efficiency of up to 86%.

Generators

Onsite generation can be divided into two categories: Prime and Emergency Standby.

Primary Generators

Prime power generators involve far more annual run hours than a pure standby application. Gas engines were designed for extended duty with lower power density and higher first cost than diesel engines. In this application fuel cost, maintenance cost, and emissions are the key concerns. Gas engines have cleaner exhaust emissions and deliver a significantly lower cost energy than diesel engines. Fast startups and rapid load acceptance are not a priority in prime power applications.

Standby Generators

Standby generators typically operate for less than 100 hours per year, and operations can be sporadic. Diesel engines have high-power density, low first cost, and can assume loads quickly during emergency startups. Fuel cost, maintenance cost, and emissions are secondary concerns for diesel generators due to low hours of annual usage.

Choosing the right on-site generation requires an understanding of the loads to be powered, the capability required of the engine to meet the loads, the site's access to cost-effective fuel, and the local emissions requirements.

At scale (greater than 1 MW), gas generation can be very competitive with grid power in terms of cost. Further, since the utilization may or go up or down, it is important to look at each site individually to determine the economics of placing on-site generators.

UPS

Uninterruptable Power Supply

UPS systems provide the ability to draw power from batteries while they're being charged. These units are used to protect critical devices that cannot lose power for even a very brief time, such as a life support system or a computer server.

To understand the benefits of a UPS system, think of it as you would a water tower. First, as long as there is water in the tower, the flow will be constant. Second, the tower can be filled and used simultaneously. A UPS system operates in much the same way. All energy flows through the unit battery so any short-term disruption in supply will not impact the flow of energy.

While UPS systems are useful for preventing power disruptions, the hardware is expensive, and these systems consume 3–4% of the energy that passes through them. When a customer has little or no tolerance for voltage dips, a UPS unit is a good tool to allow an energy system to seamlessly transition to or from the grid.

The Importance of the

Uninterruptable Power Supply

Benefits

Avoid Power Issues

A UPS protects against the following:

- Power Outage

- Power Surges

- Power Sags

- Over Voltage

- Under Voltage

- Line Noise

U.S. Fuel Cell Market Size,

by Application (Units)

Fuel cells

Fuel cells use a chemical reaction to extract energy from fuel instead of using combustion. Typically fuel cells will combine oxygen, natural gas, and a catalyst at high pressure between a cathode and anode. The outputs of the process are energy, steam and carbon dioxide. A fuel cell system is best utilized running constantly as a primary source of power and can be scaled up for large usage.

Fuel cells are not considered 100% green because of their use of natural gas. The system releases carbon dioxide when using natural gas as the feedstock, but it does so at a substantially lower rate than combine cycle natural gas turbines. Also, fuel cells do not produce harmful sulfuric and nitrogen oxides (SOx, NOx) and thus are significantly cleaner than standard diesel generators and even grid energy. Fuel cells can be configured to run using hydrogen gas instead of natural gas in which case they will only release steam.

The biggest challenge for the adoption of fuel cells that run solely on hydrogen gas is the high cost of the energy necessary to create the hydrogen gas. It is an energy-intensive process to convert water to hydrogen and oxygen and then use the hydrogen to produce energy. Likewise, capturing the carbon from a natural gas process is not currently cost-effective, though innovation in this area continues.

The levelized cost of energy from fuel cells is becoming much more competitive with current retail rates charged by utilities, particularly in coastal states. In many business cases, it makes sense to consider fuel cells, particularly if facilities are using large amounts of energy at high rates.

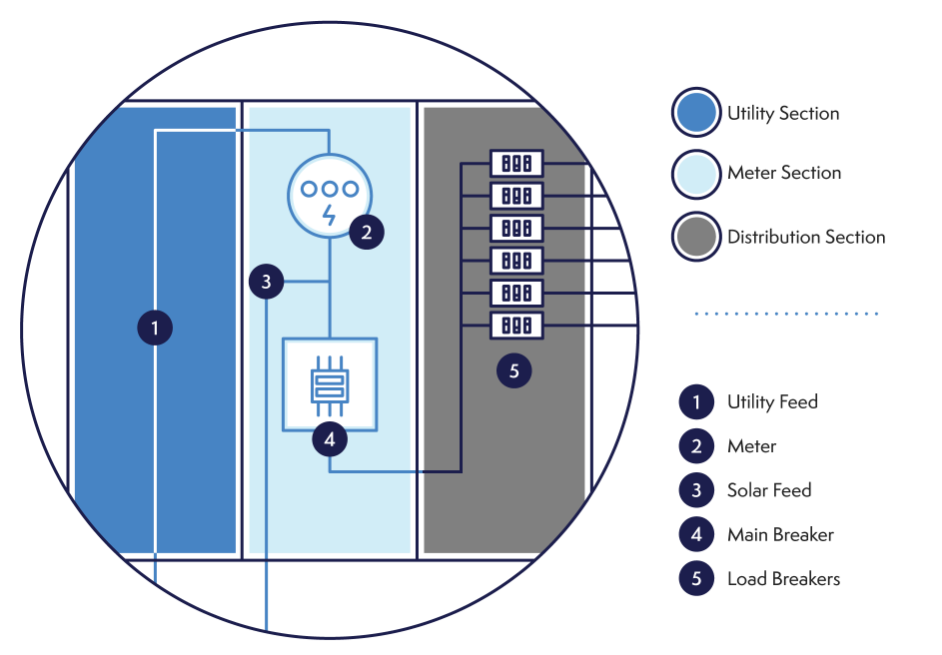

Switchgear

Like a breaker box on your home, switchgear is what brings all of the technologies together. Switchgear is standard electrical equipment that contains switches, fuses and circuit breakers at the point of connection between a facility and the grid. When a new energy system is installed on a facility, upgrades to the current switchgear may be necessary. The switchgear controls parts of the electrical system and allows segments of the full system to be taken on or off-line for maintenance or to clear faults.

The Anatomy of Switchgear